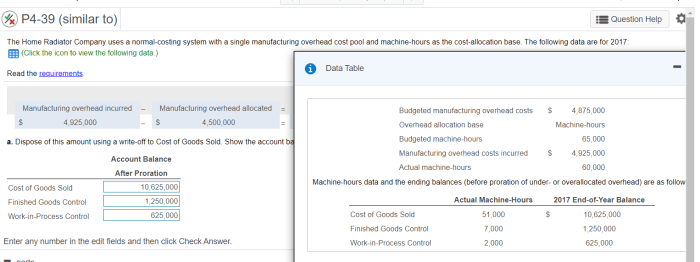

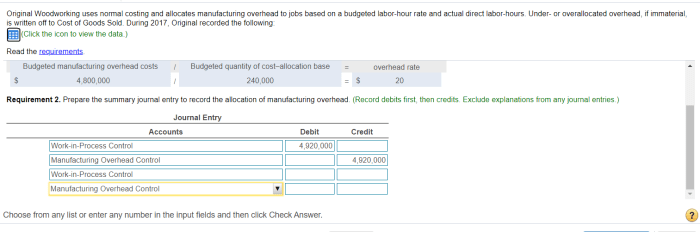

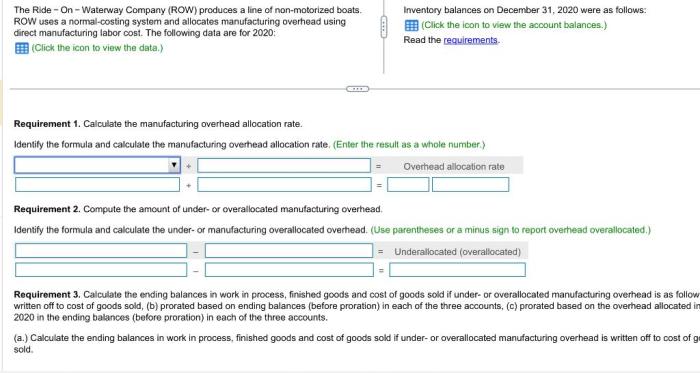

Manufacturing overhead is overallocated if the amount – Manufacturing overhead overallocation occurs when the amount of overhead costs assigned to products exceeds the actual overhead incurred during production. This discrepancy can arise from various causes, leading to distorted product costing and erroneous decision-making. Understanding the concept, causes, and consequences of overallocation is crucial for accurate financial reporting and effective cost management.

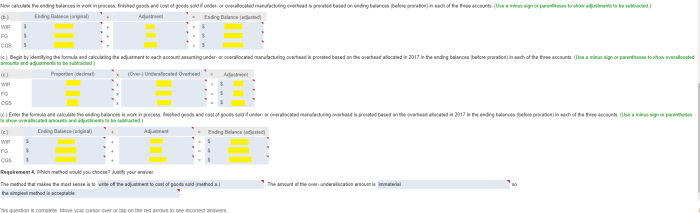

Overallocation can stem from inaccurate cost allocation methods, incorrect application of overhead rates, or changes in production volume. Its impact on financial reporting includes inflated product costs, understated profitability, and misrepresentation of cost behavior. Identifying overallocation involves comparing actual overhead costs to applied overhead costs, analyzing variances, and evaluating the reasonableness of overhead rates.

Overallocation of Manufacturing Overhead

Overallocation of manufacturing overhead occurs when the amount of overhead costs allocated to products or services exceeds the actual amount of overhead incurred. This can lead to inaccurate product costing and incorrect financial reporting.

Causes of Overallocation

Common causes of overallocation include:

- Inaccurate estimation of overhead costs

- Incorrect allocation methods

- Changes in production levels

Methods to Identify Overallocation, Manufacturing overhead is overallocated if the amount

Overallocation can be identified by:

- Comparing actual overhead costs to allocated overhead costs

- Analyzing production reports to identify underutilized capacity

- Reviewing cost allocation methods for accuracy

Consequences of Overallocation

Overallocation can lead to:

- Overstated product costs

- Understated profits

- Distorted decision-making

Strategies to Mitigate Overallocation

Strategies to mitigate overallocation include:

- Improving overhead cost estimation

- Refining cost allocation methods

- Monitoring production levels and adjusting overhead allocation accordingly

Query Resolution: Manufacturing Overhead Is Overallocated If The Amount

What are the consequences of overallocating manufacturing overhead?

Overallocation can distort product costing, leading to inflated prices and incorrect profit margins. It can also impact decision-making by providing inaccurate cost information for product pricing, production planning, and resource allocation.

How can I identify overallocation of manufacturing overhead?

To identify overallocation, compare actual overhead costs to applied overhead costs. Calculate the variance and analyze its magnitude. Additionally, evaluate the reasonableness of overhead rates and consider changes in production volume that may have affected overhead allocation.

What strategies can be implemented to mitigate overallocation?

Mitigating overallocation involves regular review of overhead allocation methods, accurate estimation of overhead rates based on current production levels, and monitoring of production volume to ensure appropriate cost allocation.