Steam enters an adiabatic turbine at 8 MPa, embarking on a thermodynamic journey that unveils the remarkable efficiency of energy conversion. This process holds significant implications for industries seeking optimized performance and reduced energy consumption.

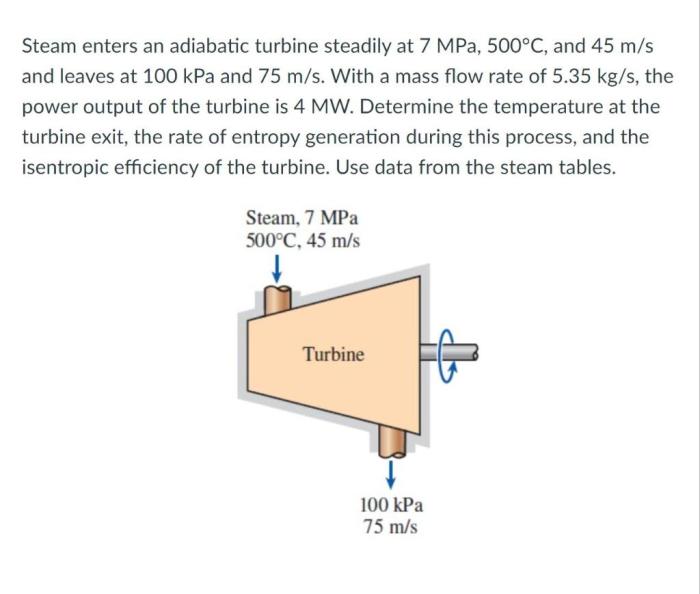

As the steam traverses the turbine, it undergoes an adiabatic expansion, a process characterized by the absence of heat transfer. This unique characteristic plays a crucial role in maximizing energy extraction and minimizing losses, making adiabatic turbines a highly sought-after technology in various applications.

Adiabatic Turbines: Steam Enters An Adiabatic Turbine At 8 Mpa

Adiabatic turbines are a type of turbine that operates without heat transfer to or from the surrounding environment. They play a crucial role in power generation, propulsion systems, and industrial processes. In this article, we will delve into the inner workings of adiabatic turbines, exploring their inlet conditions, adiabatic process, thermodynamic properties of steam, design considerations, efficiency, and applications.

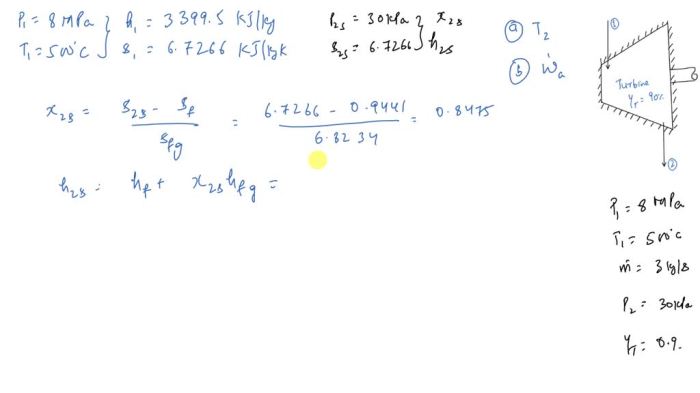

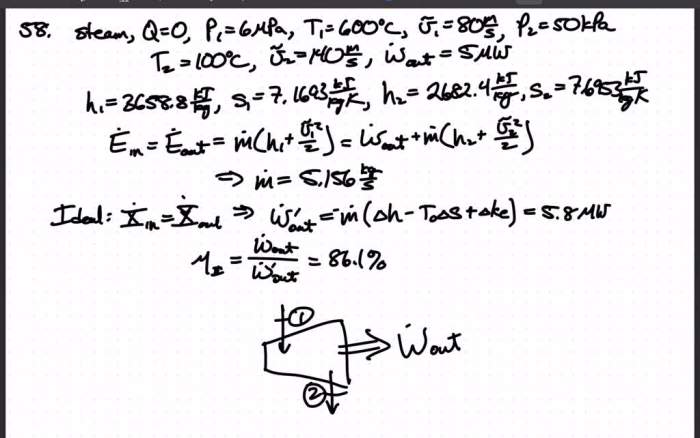

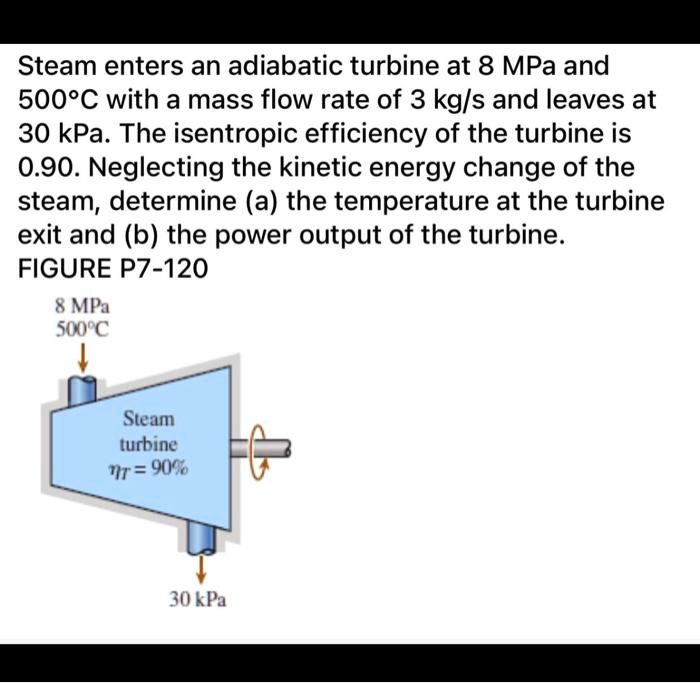

Turbine Inlet Conditions

The steam entering an adiabatic turbine is typically at a high pressure, typically around 8 MPa. This high pressure is essential for efficient turbine operation. The pressure difference between the inlet and outlet of the turbine creates the driving force for the expansion of the steam, which in turn generates power.

High-pressure steam also contributes to improved turbine efficiency. The higher the pressure, the denser the steam, resulting in a higher mass flow rate through the turbine. This increased mass flow rate leads to increased power output and efficiency.

Adiabatic Process

An adiabatic process is one in which there is no heat transfer between the system and its surroundings. In the context of adiabatic turbines, this means that the steam expands through the turbine without gaining or losing heat. This is an idealization, as there is always some heat transfer in real-world systems.

However, the adiabatic assumption is a useful approximation that allows us to understand the fundamental principles of turbine operation.

The implications of no heat transfer during turbine expansion are significant. The steam undergoes an isentropic expansion, meaning that its entropy remains constant. This results in a decrease in both temperature and pressure as the steam expands through the turbine.

Thermodynamic Properties of Steam

The thermodynamic properties of steam at 8 MPa are crucial for understanding turbine operation. The following table provides some key properties:

| Property | Value |

|---|---|

| Pressure | 8 MPa |

| Temperature | 281.3 °C |

| Enthalpy | 2799.3 kJ/kg |

| Entropy | 6.74 kJ/kg·K |

These properties influence turbine operation in several ways. The high enthalpy of the steam at the inlet provides the energy required for power generation. The low entropy of the steam indicates that the expansion process is close to isentropic, resulting in improved efficiency.

Turbine Design Considerations, Steam enters an adiabatic turbine at 8 mpa

Adiabatic turbines are designed to optimize energy conversion. The following are some key design features:

- Nozzle:The nozzle converts the high-pressure steam into a high-velocity jet. The shape of the nozzle is designed to minimize losses and maximize the kinetic energy of the steam.

- Blades:The blades are the rotating part of the turbine. They are designed to extract energy from the steam jet and convert it into rotational motion.

- Casing:The casing surrounds the blades and provides a sealed environment for the steam expansion. It is designed to withstand the high pressure and temperature of the steam.

Turbine Efficiency

Turbine efficiency is a measure of how efficiently the turbine converts the energy of the steam into rotational motion. The efficiency of an adiabatic turbine is typically around 85-90%. The following factors affect turbine efficiency:

- Adiabatic conditions:The adiabatic assumption minimizes heat losses, resulting in improved efficiency.

- Blade design:The shape and design of the blades play a crucial role in energy extraction and efficiency.

- Friction and other losses:Friction in the bearings and other mechanical losses reduce turbine efficiency.

Applications of Adiabatic Turbines

Adiabatic turbines are used in a wide range of applications, including:

- Power generation:Adiabatic turbines are used in thermal power plants to generate electricity from fossil fuels, nuclear energy, or renewable energy sources.

- Propulsion systems:Adiabatic turbines are used in aircraft engines, rocket engines, and marine propulsion systems.

- Industrial processes:Adiabatic turbines are used in various industrial processes, such as oil and gas processing, chemical production, and food processing.

Adiabatic turbines offer several advantages in these applications, including high efficiency, reliability, and versatility.

Frequently Asked Questions

What is the significance of 8 MPa pressure at the turbine inlet?

The high pressure of 8 MPa at the turbine inlet enhances the energy content of the steam, resulting in increased power output and efficiency.

How does the adiabatic process contribute to improved turbine efficiency?

The absence of heat transfer during the adiabatic expansion minimizes energy losses, maximizing the conversion of thermal energy into mechanical energy.